How To Make A Perfect Technical Drawing 9 Useful Tips

How To Make A Perfect Technical Drawing 9 Useful Tips Youtube Technical drawings give a clear and detailed view of parts, making it easy for an engineer and a cnc machinist to understand a part’s geometry and identify i. 3. cover your triangles in paper scotch tape – that is going to reduce smudging as well. paper scotch tape will remove most grime from your drawing sheet; just remember to change it from time to.

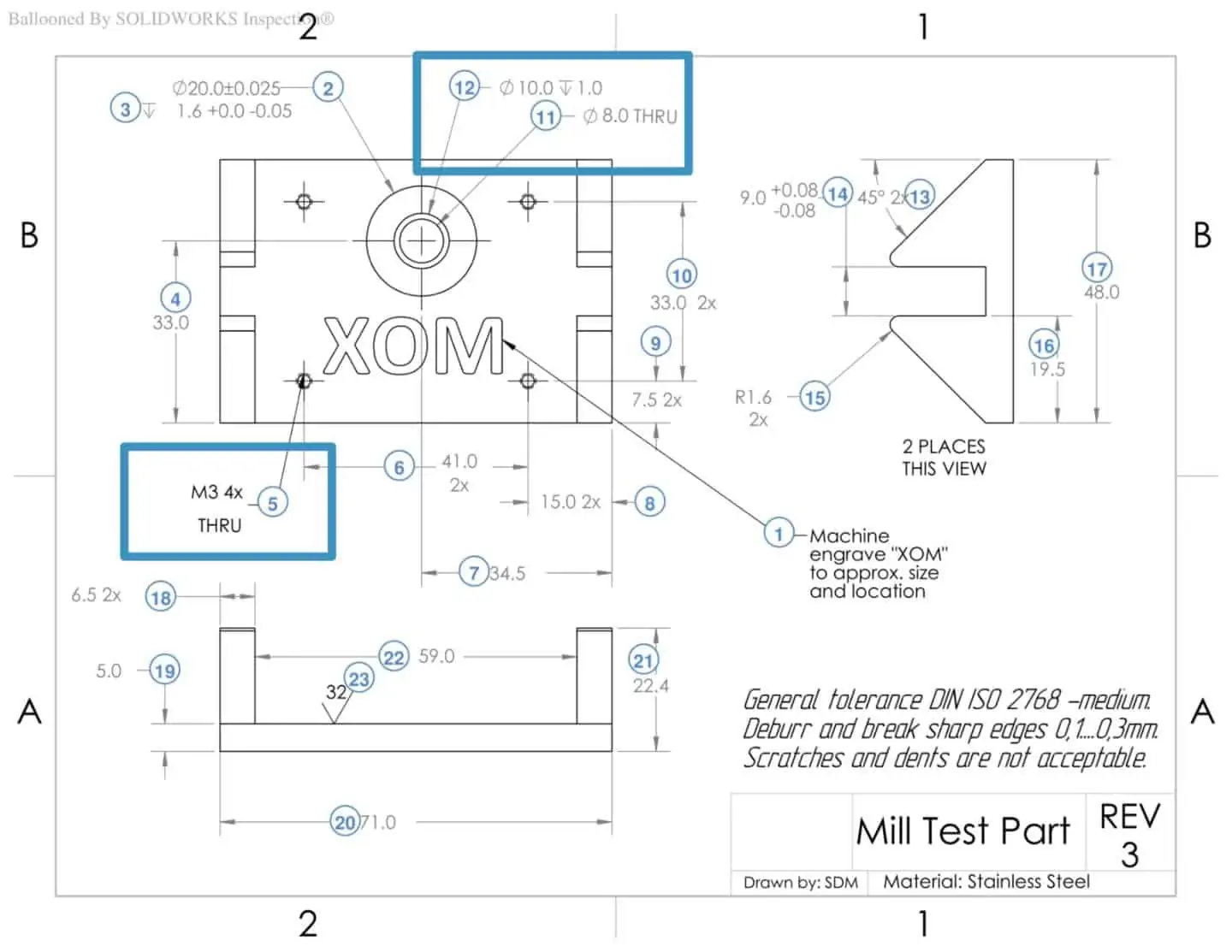

How To Prepare A Perfect Technical Drawing A Complete Guide Isometric drawing. one crucial technique to master in technical drawing is the use of three dimensional isometric drawings. isometric drawing is a method of creating a three dimensional representation of an object by drawing it on a 2d surface. it involves using equal angles and equal scales in all three dimensions, resulting in a more accurate. Step 4: create a rough sketch. rough sketching of a technical drawing. the actual drawing process begins with a rough sketch, an initial object focusing on its basic shape and layout. the rough sketch can be used as a conceptual guide to visualize the final product. 6. ensure views align with the projection view. once you start drawing, it is important to use the correct projection alignment. the person fabricating the part will use this orientation during manufacturing, so make sure that all the views follow the alignment convention that is specified in the title block. Consistent font: use a consistent, easy to read font size and style throughout your drawing. clear labels: label all parts of the drawing clearly. avoid overcrowding the drawing with too many labels in one area. standard notations: follow industry standards for notations, such as using “Ø” for diameter or “r” for radius.

How To Prepare A Perfect Technical Drawing Xometry Europe 6. ensure views align with the projection view. once you start drawing, it is important to use the correct projection alignment. the person fabricating the part will use this orientation during manufacturing, so make sure that all the views follow the alignment convention that is specified in the title block. Consistent font: use a consistent, easy to read font size and style throughout your drawing. clear labels: label all parts of the drawing clearly. avoid overcrowding the drawing with too many labels in one area. standard notations: follow industry standards for notations, such as using “Ø” for diameter or “r” for radius. In this article, you’ll learn how to make a general technical drawing and get tips on specific technical drawings for cnc machining, sheet metal fabrication, injection molding, and extrusion. you’ll also find a concise 10 step guide to help you create a standard technical drawing for a part or product. Tip #2: communicate hole tapping needs for threaded fasteners. surprisingly, tapped hole specifications for future threaded fastener installation can be complex. so, make sure you’re utilizing the correct thread size and shape callout per the type of thread pattern you desire (i.e., acme, unc, unf, or mj).

Comments are closed.