How To Prepare A Perfect Technical Drawing Xometry Europe B85 Sheet Metal Drawing Metal

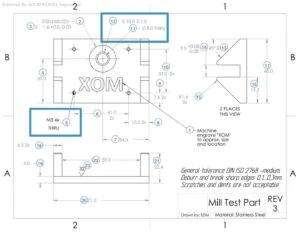

How To Prepare A Perfect Technical Drawing Xometry Pro The following are the steps you need to take, together with some tips, to prepare the perfect technical drawing. step 1. select your template. there are standard astm, din, and iso templates that specify the coordinates, angle of protection, and title block characteristics. 6. ensure views align with the projection view. once you start drawing, it is important to use the correct projection alignment. the person fabricating the part will use this orientation during manufacturing, so make sure that all the views follow the alignment convention that is specified in the title block.

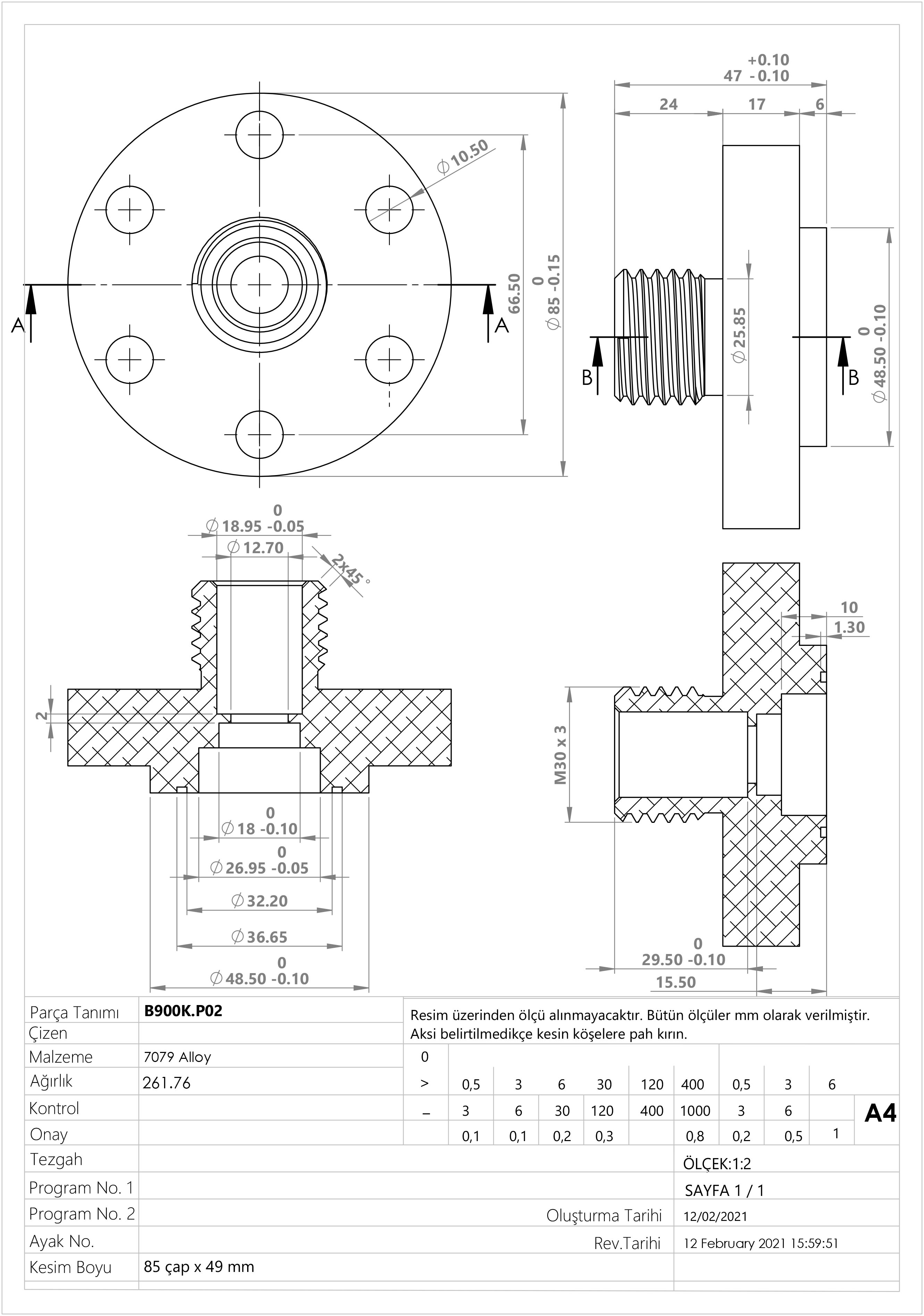

How To Prepare A Perfect Technical Drawing Xometry Europe 46 Off How to submit a perfect technical drawing so that your manufacturer can produce your parts and fulfill all of your requirements in the best possible way. Team xometry. this article was written by various xometry contributors. xometry is a leading resource on manufacturing with cnc machining, sheet metal fabrication, 3d printing, injection molding, urethane casting, and more. improve your 2d technical drawings by following our best practices covered in this free ebook. Technical drawings give a clear and detailed view of parts, making it easy for an engineer and a cnc machinist to understand the geometry of a part. it also helps them understand the part’s function, dimension, and key features. best of all, technical drawings can be submitted quickly and easily in the xometry instant quoting engine. For sheet metal parts, it is good to indicate countersinks milling in 3 dimensions on the plans and to indicate the largest diameter as well as the angle. for an angle corresponding to a 45° chamfer (the most classic), one traditionally indicates a milling at 90°, which corresponds to the angle of the cone of the milling cutter or punch used.

How To Prepare A Perfect Technical Drawing Xometry Pro Technical drawings give a clear and detailed view of parts, making it easy for an engineer and a cnc machinist to understand the geometry of a part. it also helps them understand the part’s function, dimension, and key features. best of all, technical drawings can be submitted quickly and easily in the xometry instant quoting engine. For sheet metal parts, it is good to indicate countersinks milling in 3 dimensions on the plans and to indicate the largest diameter as well as the angle. for an angle corresponding to a 45° chamfer (the most classic), one traditionally indicates a milling at 90°, which corresponds to the angle of the cone of the milling cutter or punch used. Xometry’s sheet metal tolerance offerings if a drawing or specification sheet has not been provided by the customer, xometry will manufacture the product from the model to the specifications listed below: tolerances • forming and bending: 0.020” • bend to hole or feature: 0.010”. Technical drawings give a clear and detailed view of parts, making it easy for an engineer and a cnc machinist to understand the geometry of a part. it also helps them understand the part’s function, dimension, and key features. best of all, technical drawings can be submitted quickly and easily in the xometry instant quoting engine®.

Comments are closed.