Poppet Valve Mechanical Device Britannica

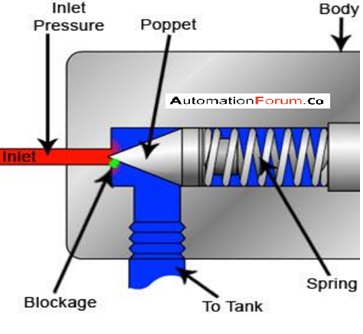

Poppet Valve Mechanical Device Britannica Valve, in mechanical engineering, device for controlling the flow of fluids (liquids, gases, slurries) in a pipe or other enclosure. control is by means of a movable element that opens, shuts, or partially obstructs an opening in a passageway. valves are of seven main types: globe, gate, needle, plug (cock), butterfly, poppet, and spool. A poppet valve (also sometimes called mushroom valve[1]) is a valve typically used to control the timing and quantity of petrol (gas) or vapour flow into or out of an engine, but with many other applications. it consists of a hole or open ended chamber, usually round or oval in cross section, and a plug, usually a disk shape on the end of a.

What Is Poppet Valve Poppet Valve Working Animation Part 1 Youtube Valve, in mechanical engineering, device for controlling the flow of fluids (liquids, gases, slurries) in a pipe or other enclosure. control is by means of a movable element that opens, shuts, or partially obstructs an opening in a passageway. valves are of seven main types: globe, gate, needle, plug (cock), butterfly, poppet, and spool. The two major valves used most commonly are the poppet and piston spool varieties. these valves are primarily involved with controlling compressed air. “the main difference between a spool and a. Sleeve valve versus poppet valve story because it should be of general interest to the enthusiast of aircraft engines and most of the arguments can be understood by non engineers, although the analysis may be out of reach to some. the story also illustrates the difficulty in introducing a major variation into the design of a device already well. 3 2 poppet valve; 4 2 poppet valve; 2 2 poppet valve. the figure below shows the construction and symbol of a simple 2 2 normally closed valve. the release of the pushbutton lifts the ball off its seat and allows fluid to flow from port p to port a. when the button is released, spring and fluid pressure force the ball upward again, closing the.

What Is Poppet Valve Uses And Working Sleeve valve versus poppet valve story because it should be of general interest to the enthusiast of aircraft engines and most of the arguments can be understood by non engineers, although the analysis may be out of reach to some. the story also illustrates the difficulty in introducing a major variation into the design of a device already well. 3 2 poppet valve; 4 2 poppet valve; 2 2 poppet valve. the figure below shows the construction and symbol of a simple 2 2 normally closed valve. the release of the pushbutton lifts the ball off its seat and allows fluid to flow from port p to port a. when the button is released, spring and fluid pressure force the ball upward again, closing the. Abstract. mechanical prosthetic valves were first implanted to replace diseased mitral and aortic valves in 1960. the initial models were developed according to the caged ball design, with a moving poppet contained into a metallic frame. subsequent models included caged disc, tilting disc, and bileaflet designs. The poppet valves generally have self cleaning tendency as the large relative valve opening produces a large flow through it, sweeping away contaminates resides over the surface of the valve. the poppet valves are commonly employed for pressure holding and pressure release in the single acting cylinder engines.

What Is A Poppet Valve And What Does It Do Instrumentation And Control Engineering Abstract. mechanical prosthetic valves were first implanted to replace diseased mitral and aortic valves in 1960. the initial models were developed according to the caged ball design, with a moving poppet contained into a metallic frame. subsequent models included caged disc, tilting disc, and bileaflet designs. The poppet valves generally have self cleaning tendency as the large relative valve opening produces a large flow through it, sweeping away contaminates resides over the surface of the valve. the poppet valves are commonly employed for pressure holding and pressure release in the single acting cylinder engines.

Comments are closed.