What Is Inventory Management Video Supply Management Logistics

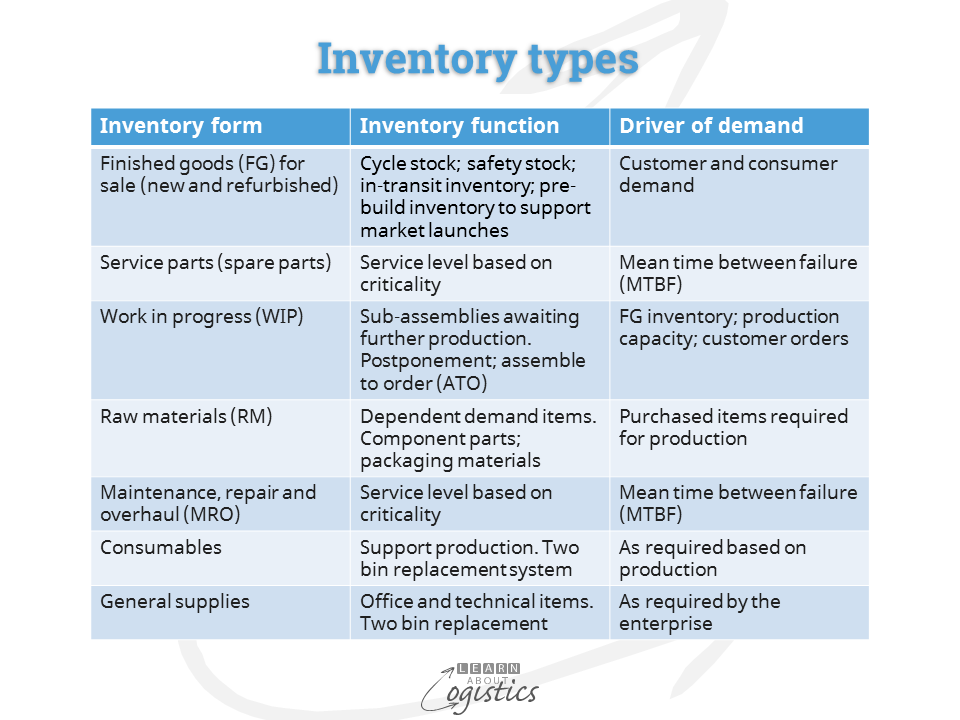

What Is Inventory Logistics 2024 Comprehensive Guide Manufacturing inventory management is the practice of keeping enough stock on hand so production lines can fulfill orders. the process helps managers see stock levels at a glance and tracks raw materials, parts, work in progress and finished goods. find out more about manufacturing inventory management. Inventory management, a critical element of the supply chain, is tracking inventory from manufacturers to warehouses and from these facilities to the point of sale. inventory management aims to have the right products in the right place at the right time. inventory management requires inventory visibility, knowing when to order, how much to.

Why Inventory Management Plays A Crucial Role In The Logistics Industry Inventory management versus inventory control. inventory control focuses on the movement of products within a specific warehouse, while inventory management is the process of tracking inventory across an entire organization that may have multiple locations and warehouse facilities. Inventory management in logistics is an essential part of the supply chain management network that helps formulate, organize, implement and control the efficient flow of goods. it is a complex process that aims to move inventories effectively in the supply chain while elevating customer satisfaction. it also assists in maintaining cost control. The primary benefit of inventory management is that it facilitates an efficient and productive approach to controlling stock. when inventory levels, storage locations, and stock control processes are fully optimised your operational efficiency increases – resulting in fewer costs and faster order fulfilment. 2. Just in time management (jit) is a strategy where inventory is delivered only as it is needed in the production process, reducing the cost of storing inventory. significant for industries like automotive manufacturing, jit can lead to reduced inventory levels and associated costs, promoting an efficient supply chain.

Inventory Management Is A Core Part Of Your Logistics Learn About Logistics The primary benefit of inventory management is that it facilitates an efficient and productive approach to controlling stock. when inventory levels, storage locations, and stock control processes are fully optimised your operational efficiency increases – resulting in fewer costs and faster order fulfilment. 2. Just in time management (jit) is a strategy where inventory is delivered only as it is needed in the production process, reducing the cost of storing inventory. significant for industries like automotive manufacturing, jit can lead to reduced inventory levels and associated costs, promoting an efficient supply chain. Inventory management in logistics involves overseeing the flow of goods from suppliers to warehouses and from these facilities to customers. it requires accurate tracking, timely reordering, and efficient storage solutions. by maintaining optimal inventory levels, businesses can meet customer demand while keeping costs under control. 1. better inventory planning and supply management. this might be the main benefit of employing inventory management techniques in the logistics sector, as it will impact many aspects of the business. it all starts with excellent planning. the effects will be felt across all stages, from storage and sales to shipping.

What Is Inventory Management 101 Benefits Techniques Objectives More Inventory management in logistics involves overseeing the flow of goods from suppliers to warehouses and from these facilities to customers. it requires accurate tracking, timely reordering, and efficient storage solutions. by maintaining optimal inventory levels, businesses can meet customer demand while keeping costs under control. 1. better inventory planning and supply management. this might be the main benefit of employing inventory management techniques in the logistics sector, as it will impact many aspects of the business. it all starts with excellent planning. the effects will be felt across all stages, from storage and sales to shipping.

Why Inventory Management Plays A Crucial Role In The Logistics Industry

Comments are closed.