What Is The Best Material For A Heat Exchanger Tube Marine Management

What Is The Best Material For A Heat Exchanger Tube Marine Management Based on thermal modeling comparisons using htri software, copper and copper nickel are typically the most conductive material available for exchanger tubes. carbon steel, stainless steel, and higher alloys are slightly less efficient, but all perform similarly. plastics, graphite composites and ceramics are the least conductive materials. Selecting reliable heat exchanger tube materials – factors to consider presented at: api power chem 2014 novotel twin waters, sunshine coast, queensland may 27, 2014 presented by: daniel s. janikowski technical manager plymouth tube company 2061 young street east troy, wi 53120, usa phone 1 262 642 8365 djanikowski@plymouth.

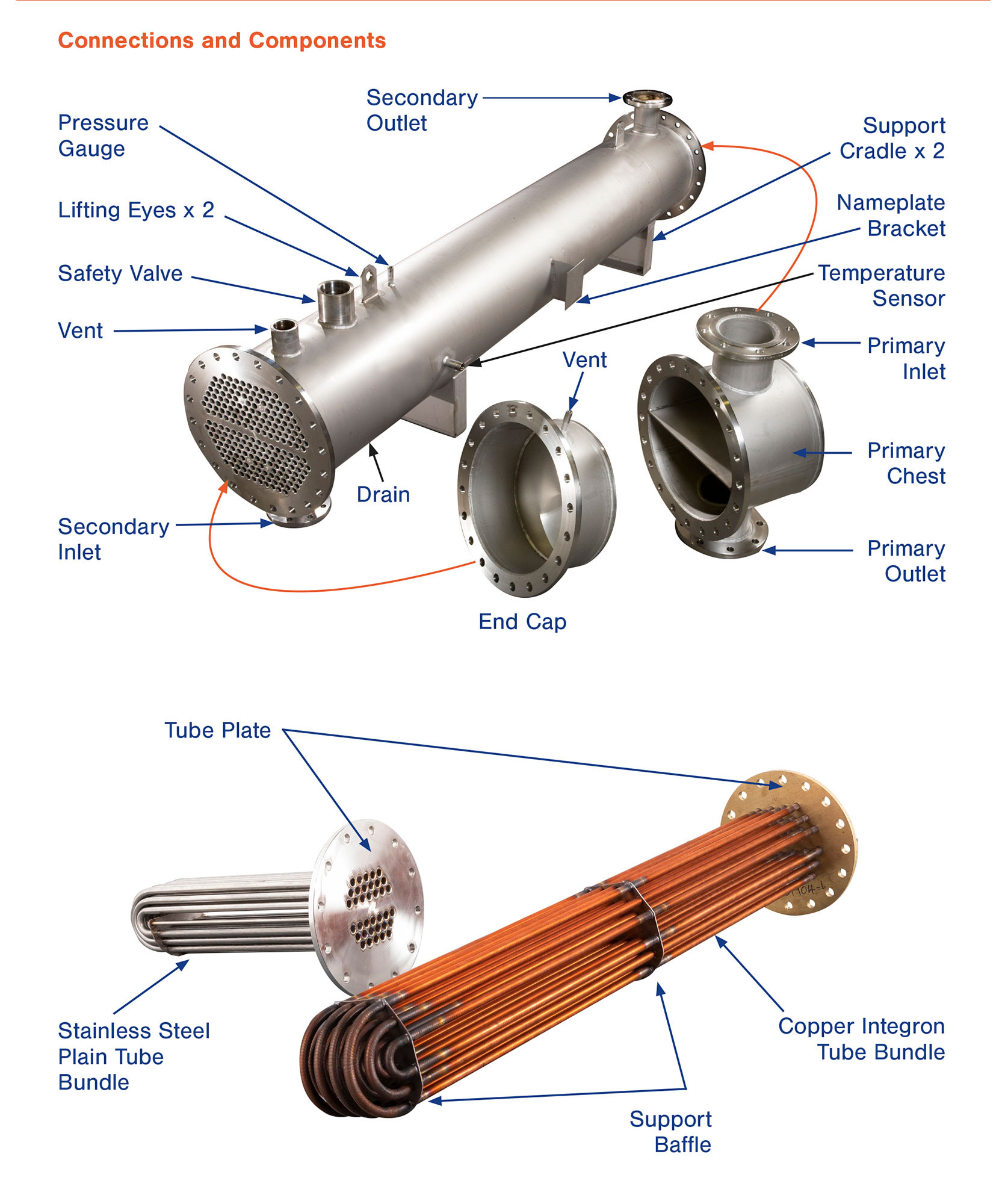

Shell Tube Heat Exchangers For Process Applications Ormandy Rycroft Engineering If this is the case, tubes made from inert materials are ideal. the two most commonly used materials for heat exchanger tubes are aluminium and copper. both ensure optimum thermal properties and corrosion resistance but the differences tend to be application specific. copper heat exchangers. copper is the most thermally conductive metal on the. Er industries that require compact design and large volume capacity. typical materi. s include titanium, stainless steel, carbon, brass and other alloys. united performance metals offers stainless steel 304 304l, 316 316l, 321, 347, 410, nickel alloy 625, and duplex stainless. steel 2205 that may be a good fit for shell and tube heat exchangers. Figure 1. hexoloy is one of the highest performing materials on the market. source: saint gobain for applications in which all three metrics are important if not essential, the best choices will be ceramic materials. for heat exchanger tubes, typically silicon carbide (sic) based ceramics are selected. a particular sic called hexoloy is an. Comparison of the best materials for heat exchanger design. now that you know the pros and cons of the materials, you can utilize the tables below — which have the key data points for each — to simplify material selection for your next heat exchanger design: thermal conductivity (btu hr*ft*f) copper. 6.95. stainless steel.

Comments are closed.